Trade Study

Have you ever been in those situations where you had many options to solve a problem? You were confused on which option will be the most optimum solution, because each option had its own pros and cons. Now let’s extend that situation to the engineering context. For instance, when you are thinking of manufacturing a car, you may care about the safety, cost and top speed, but the significance of these factors individually is likely unique. This is when a trade study comes into the picture.

A trade study, also known as a trade-off analysis, is a method used for making a decision between competing options and identifying the most balanced solution considering all the contributing factors such as measures of effectiveness, acceptance criterias, requirements, etc.

Furthermore:

- Informal trade studies are frequently performed mentally to make decisions, but formal trade studies help in objectively removing bias from certain options and refining the decision.

- These studies are the most useful when there are many different options and attributes, each of which holding unique significance, that must be considered for making a decision. For instance, when selecting a drone you may care about weight, flight duration, and cost, but each of these factors have unique significance.

A trade study compares a number of different solutions to see whether and how well they satisfy a particular set of criteria. Each solution is characterized by a set of measures of effectiveness (MOE’s) that corresponds to evaluation criteria and has a calculated value or value distribution. The MOE’s for a given solution is then evaluated using an objective function, and the results for each alternative are compared to select a preferred solution.

For the purpose of this article our system of interest is a drone and the objective chosen is to figure out the most favorable combination of parts for a drone system which will be used for cinematography application based on our requirements.

A drone that will be used for any cinematography application will be expected to have great maneuverability, battery backup and camera quality. Hence, the parts that we will be taking under consideration are the battery, the camera and the frame. We will be comparing parts of similar technical specifications (which led to our confusion in selecting these parts) but different attributes such as, mass and cost.

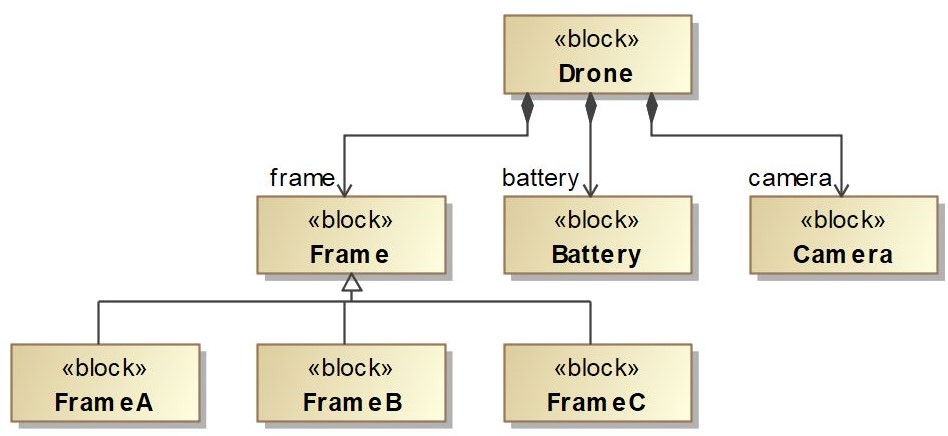

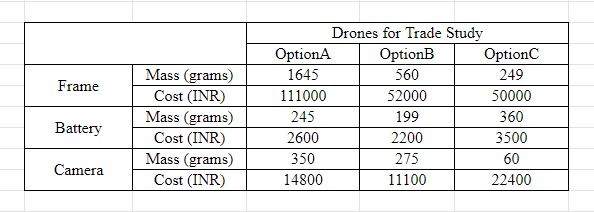

The scope of our experiment is expressed using the following image and table:

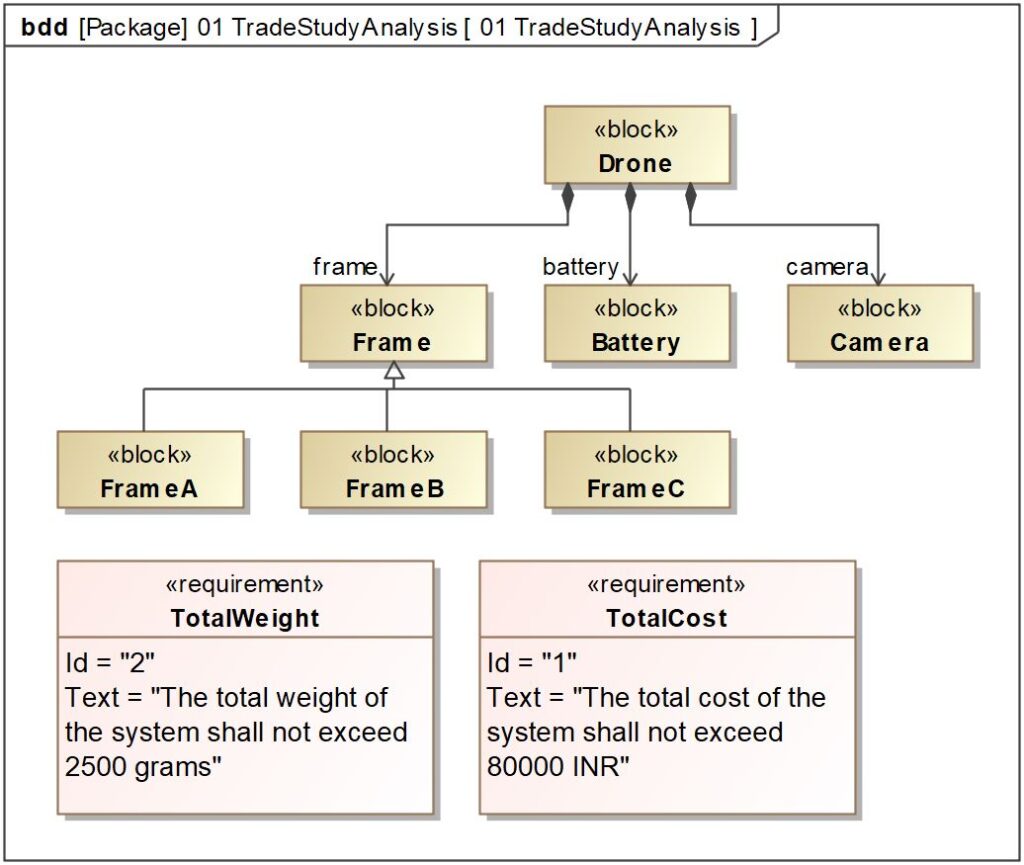

a. The figure below shows the parts whose option combination is to be decided :

b. The table below shows the value of attributes of each part with respect to the options under consideration :

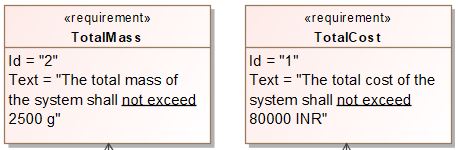

Also, to further optimize our desired results, we must define some boundaries for our attributes in the form of requirements, an example is shown below :

Trade Study Process:

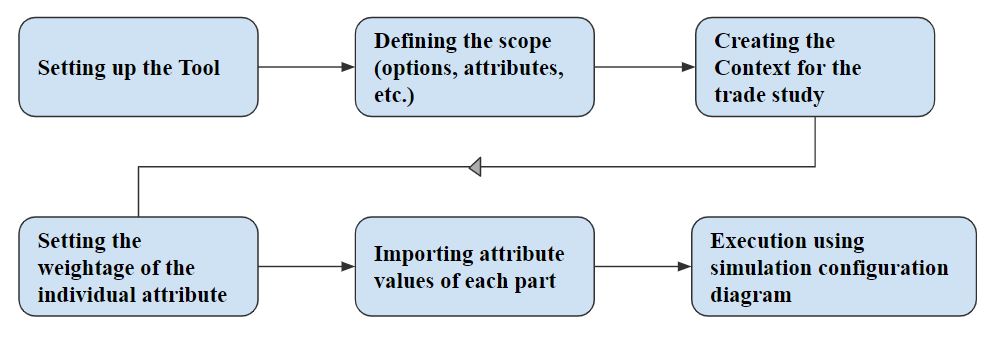

For this process, we will be following the undermentioned flowchart showing the process stepwise :

- We will be performing a trade study in the MagicDraw tool using Cameo Simulation Toolkit, to figure out which combination of parts will be the perfect combination for our desired application.

To setup the tool for our system’s trade study, we need to enable a few optional properties within the tool :

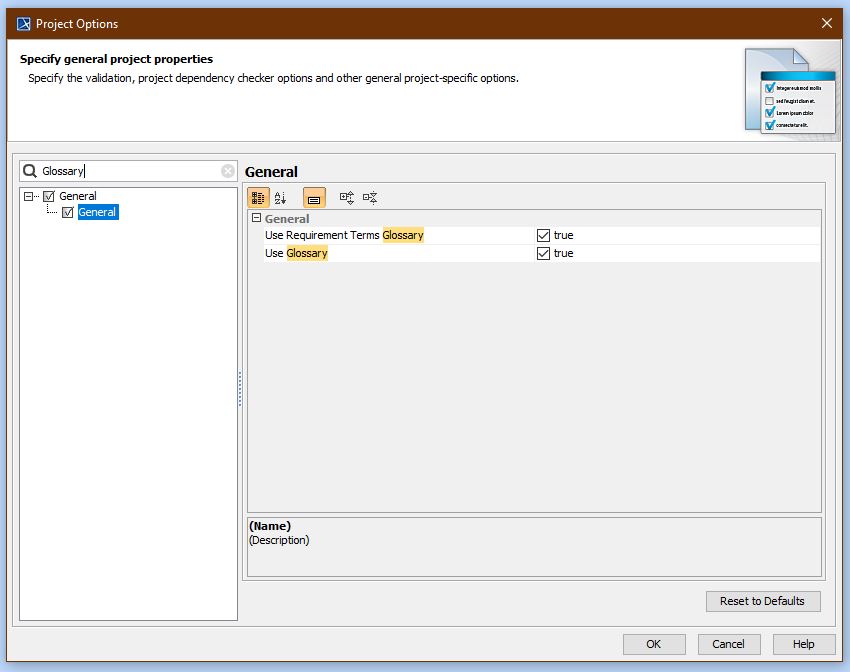

- Enable “Use Requirement Terms Glossary” (as shown below) :

- Go to Options → Project → General → Use Requirement Terms Glossary [true]

- This allows us to extract constraints from requirements automatically

- Enable “Use Requirement Terms Glossary” (as shown below) :

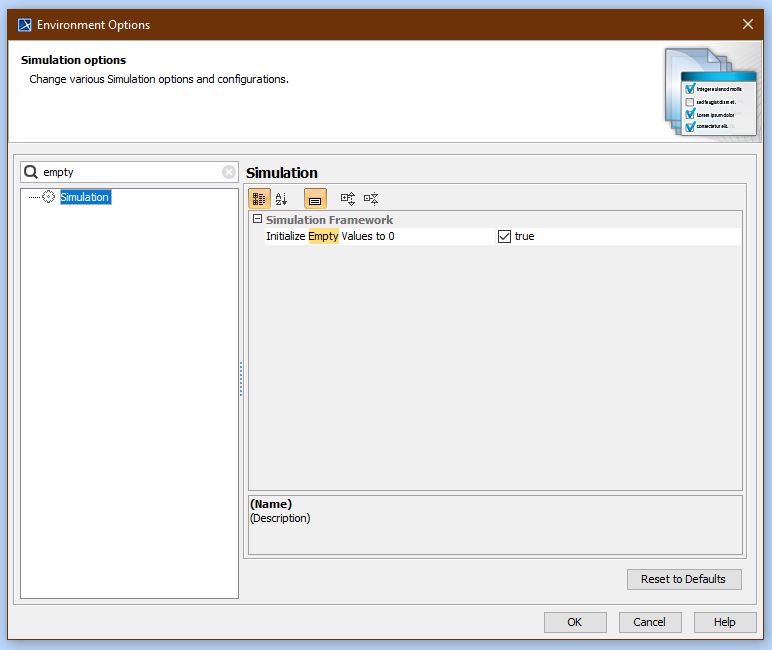

- Enable “Initialize Empty Values to 0” (as shown below) :

- Go to Options → Project / Environment (depends upon the version of the tool) → Simulation → Initialize Empty Values to 0 [true]

- When a value property has no default value, the value will be initialized to 0 value. (For simulation)

Now we begin,

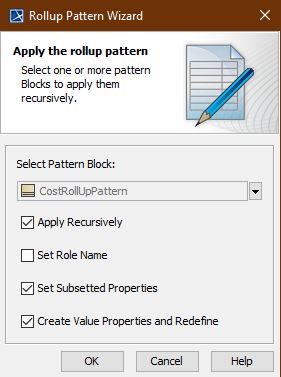

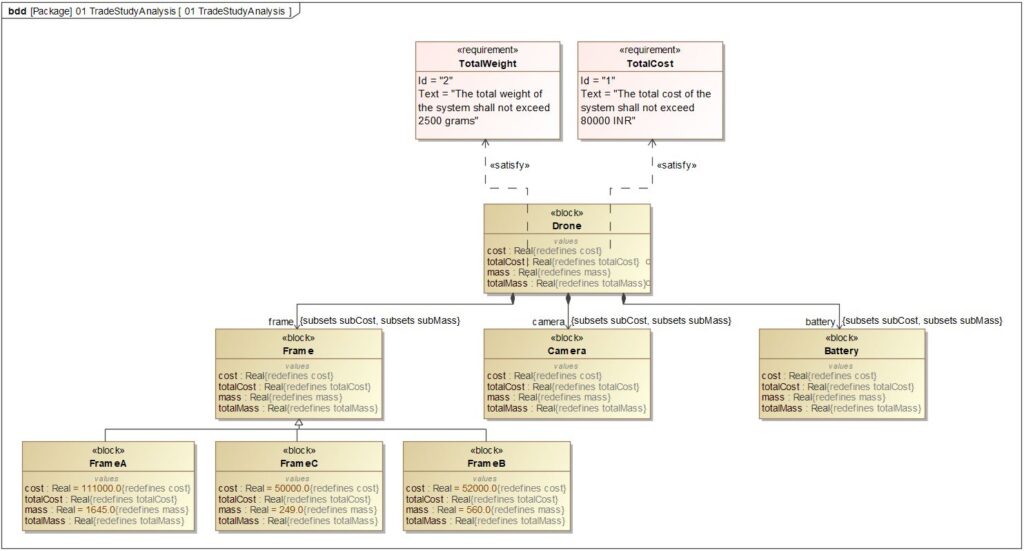

- Create a new BDD showing the system and the parts on which trade study needs to be performed as well as the requirements. (as shown below) and apply required Rollup Pattern (cost and mass in this instance)to the system block (as shown below)

a. Right click on the system block → tools → Apply Rollup Pattern → Create value properties and redefine → Select Pattern block (as required) → OK

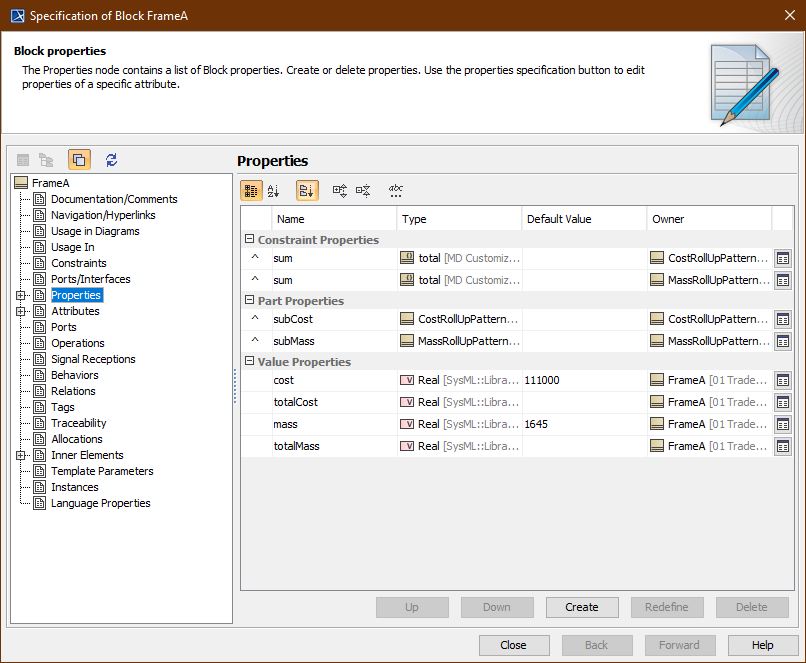

b. For blocks that are “generalized” the value properties needs to be redefined for them to be initialized, you can do that by following below mentioned steps :

i. Go to specifications of the block → Properties → Redefine all value properties from the rollup pattern (mass, cost, totalMass, etc.)

ii. you can also set up default values for each property

c. Finally satisfy the requirements using value properties from individual block as needed (as shown below)

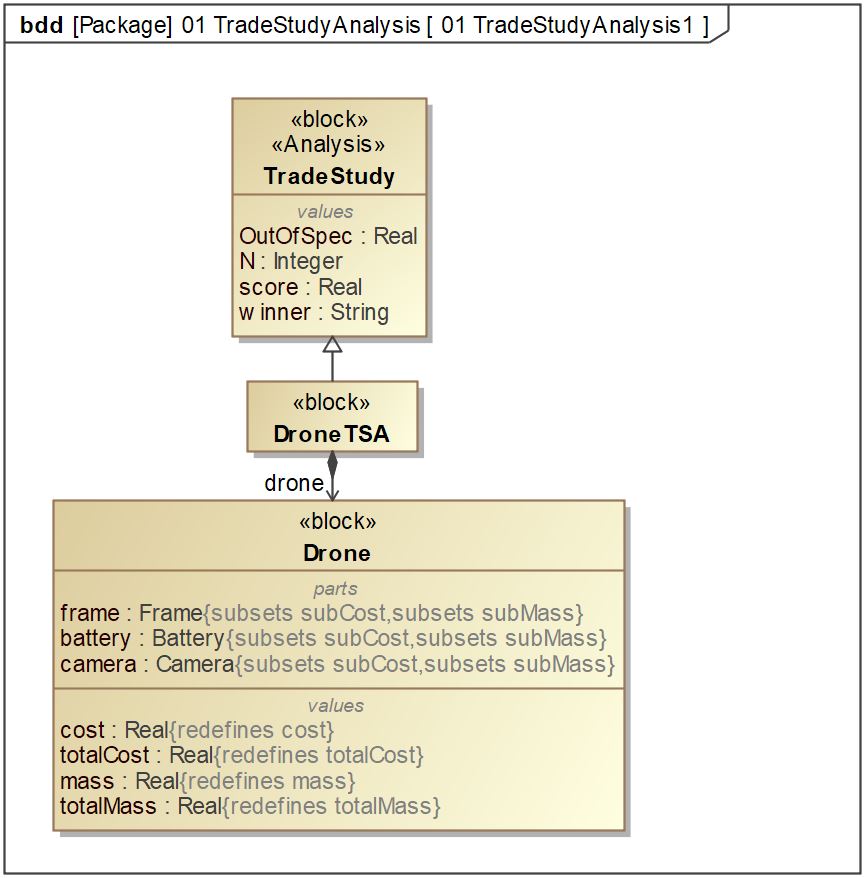

2. Next, we need to create a trade study context for our system (Drone) :

a. Create another BDD and drag the system block inside it, create another block representing the context for the system and finally drag the predefined trade study block from the containment tree as shown :

i.Show Auxiliary Resources → MD customization for SysML → Analysis patterns →trade study → TradeStudy <<block>>

ii. Inherit into the context block from the TradeStudy block to get all required properties inside of the context

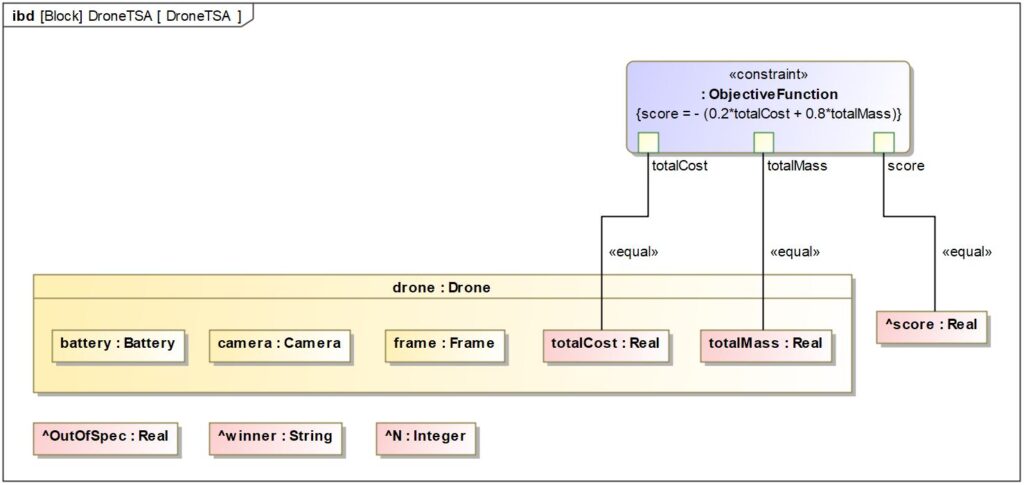

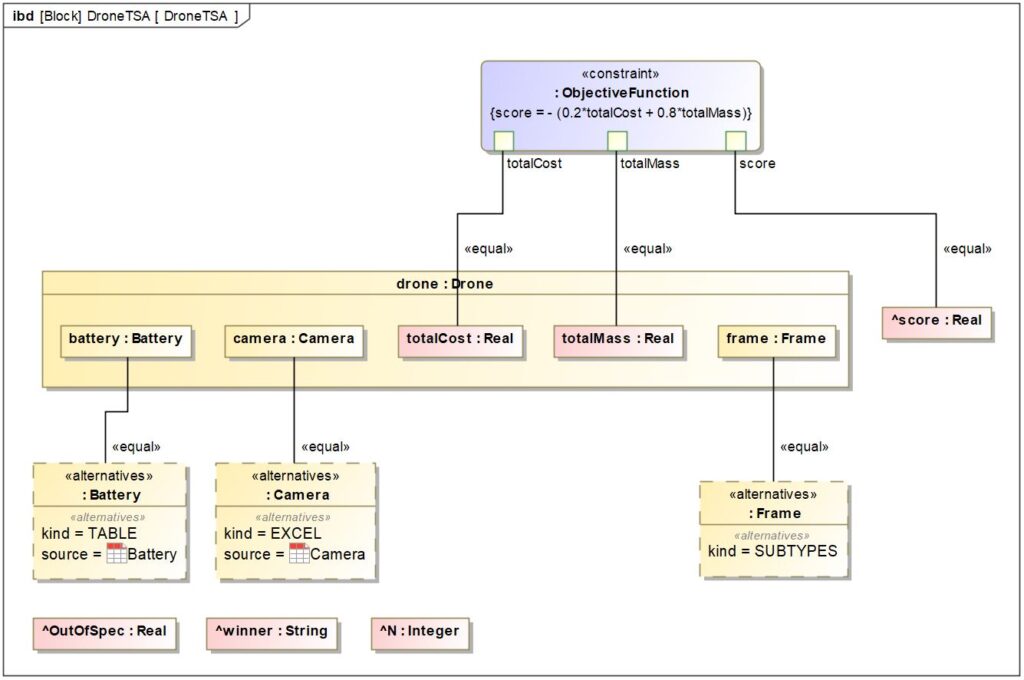

3. Create an IBD in the context block and display the parts, the totalCost and totalMass value properties and the value properties of the TradeStudy block

a. Introduce a constraint property that will calculate the score for every option

b. The constraint equation is written along with the weightage of each attribute (weightage can be decided using various methods such as customer survey,internal survey,linear weighting, etc., to reduce the risk of favoritism affecting the results)

c. A negative sign is added to the equation if the lower the value the better (like in case of cost, mass, etc.) as automatically the biggest scoring option is set as “winner”

4. To get value inputs for each part of the system we create reference properties, drag respective part blocks onto the reference property, connect them with the part inside the system using a binding connector, and finally set the stereotype as “alternative”. (Stereotype is hidden by default you can unhide it from symbol properties)

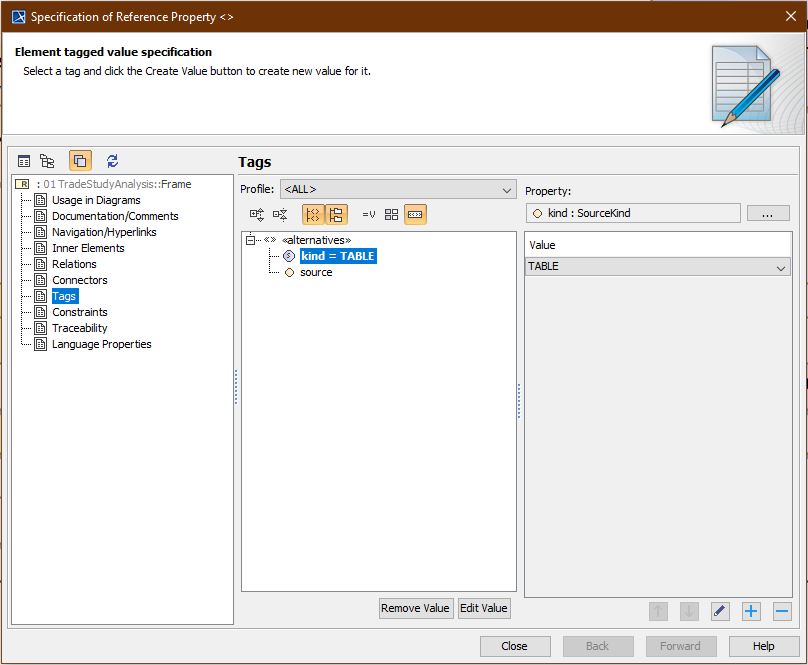

a. You can set Kind and Source of data for each alternative by :

i. Go to specification → Tags → Kind and Source

ii. Kind can be Table (instance table), Excel or Subtypes, Source is the instance table where data is written or instance table which is synced to an excel file

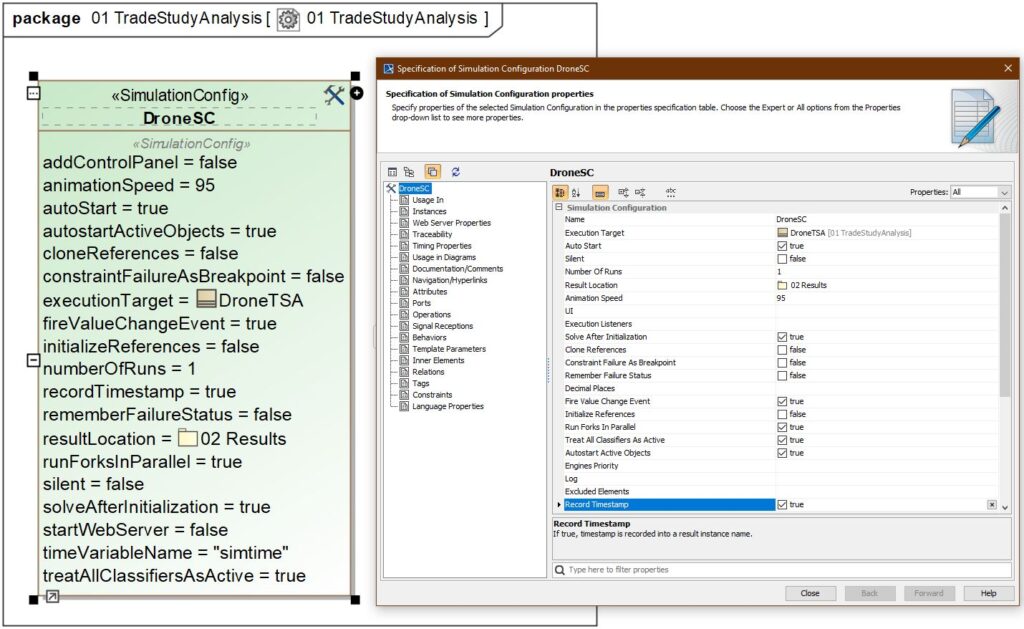

5. To run this study we need to create a simulation configuration diagram

a. Set the context block as the execution target, set a package as the result location (where instances will be stored),you can record timestamp for later reference

b. Create an instance table in the results package with the context block as classifier and results package as scope

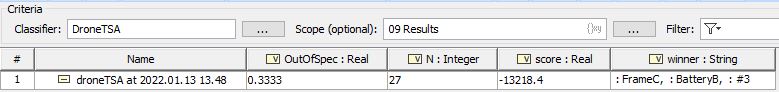

6. Now you can run this simulation and the results will appear inside the set instance table. You can see the ratio of the number of options that failed, the number of simulations run, the score of the winning combination and the winning combination

This is how we can simplify the process of going through each and every combination of available options and chosen attributes to find the set of options that are the most appropriate solution for our problem by performing a trade study.

Conclusion:

Trade study can be used to identify the most acceptable solution among a set of proposed suitable solutions. Solutions of trade study are concluded based on their satisfaction of a set of properties, which may be in agreement, disagreement or unique.

Any biases that we have when selecting the weightage of an attribute will impact the results. Hence, the results should not be considered to be perfect. To reduce any bias, a study can be performed to see the sensitivity of results based on changes in attribute values and weightages. Or the weightages can be selected based on a product survey from consumers, etc.

Trade study can be used to satisfy multiple objectives such as :

- Alternative designs based on performance, cost, -ilities, etc.

- Deciding on COTS (commercial off the shelf) products for purchase

- Reducing risk by having explored all options in the design space, and many more.

If you are interested in understanding how to adopt systems engineering and model based systems engineering practices within your organization, reach out to BlueKei Solutions team at info@Blue-Kei.com. We specialize in systems engineering consulting, project executions, process adoptions such as compliance to ISO15288, ARP 4754A, ISO 42020, digital transformations. We can also conduct capability development workshops which are experiential and tailored to your needs. With systems engineering adoption you can address the complexity, manage evolving risks and bring transformation in communication within your organization through digitalization and create the digital thread.