Harnessing the Power of Simulation and Modelling in Systems Design and Analysis

Complex systems are the backbone of our modern world, from towering skyscrapers to intricate networks powering our cities. Designing and analysing these systems effectively requires robust methodologies. Enter Systems Design and Analysis (SDA), a cornerstone practice that empowers engineers to create high-performing systems.

SDA entails a comprehensive approach, meticulously dissecting system requirements, crafting the system’s architecture, and rigorously analysing its functionality. Through SDA, engineers can ensure the systems they design are efficient, reliable, and meet the ever-evolving needs of stakeholders.

One of the most powerful tools within the SDA toolbox is the combined force of simulation and modelling. These techniques offer a practical solution for tackling the challenges that arise when designing and analysing intricate systems. According to a study by INCOSE, a staggering 94% of participants reported improved project success rates by leveraging systems engineering practices, which heavily rely on simulation and modelling.

This blog post delves into the fascinating world of simulation and modelling, exploring their significance, real-world applications, the underlying processes, the instruments used, the potential benefits, the challenges to consider, recommended approaches, and inspiring examples in action. By the time you reach the conclusion, you will possess a clear understanding of how simulation and modelling can revolutionize your business by enabling breakthrough systems design.

Simulation and modelling entail replicating actual situations and systems in a managed setting. Simulation involves developing a digital representation of a system and observing its operation in various scenarios. Modelling involves simplifying a system through mathematical, physical, or behavioural methods to create a representation. Several types of simulations include discrete-event, continuous, and agent-based while modelling methods encompass mathematical, physical, and behavioural models.

- Aerospace and Defence:Optimize aircraft designs, simulate flight conditions, and analyse mission outcomes. For instance, Rolls-Royce uses Ansys software to simulate jet engines for achieving net-zero emissions.

- Automotive and Transportation:Enhance vehicle performance and test safety measures. One example is the application of Computational Fluid Dynamics (CFD) simulations to reduce drag on car designs.

- Manufacturing and Production:Optimize processes to improve product quality.

- Healthcare and Life Sciences: Develop drugs, analyse patient flow, and simulate surgeries. Siemensoffers simulation tools specifically designed for medical devices and pharmaceutical processes.

- Energy and Utilities: Optimize energy use and analyse power grids.

- Construction and Infrastructure:Plan and optimize projects.

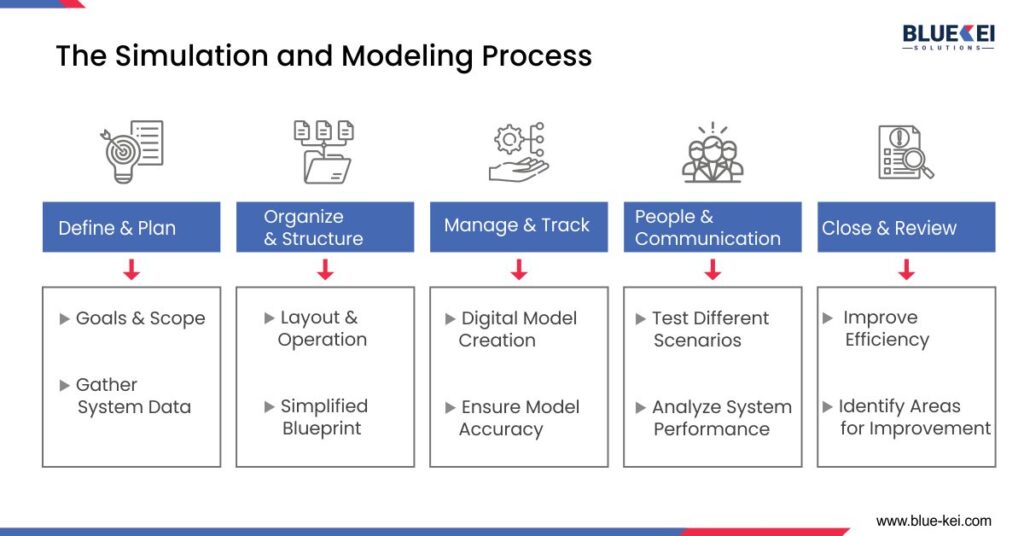

The simulation and modelling procedure consist of several crucial stages. The process begins by defining the problem and gathering requirements. This initial phase establishes the project’s goals and scope, which outlines the boundaries and complexity of the simulation. Next comes the system design and analysis modelling phase, where the layout and operation of the system are defined. Following this, model creation and validation occur; this step ensures the simulation accurately reflects the actual system by comparing it to established criteria. Once validated, simulation execution and analysis are conducted to observe and scrutinize the system’s behaviour under various conditions. Finally, the knowledge gained from the simulation is used for optimization and decision-making, allowing engineers to make strategic choices and improve the system.

- Computer-Aided Design (CAD) and Computer-Aided Engineering (CAE) Tools Engineers may build, test, and refine physical systems in virtual environments using SolidWorks, AutoCAD, and ANSYS. CAD tools are needed for precise designs, whereas CAE tools simulate structural integrity, thermal performance, and stress responses. This integration finds defects before physical prototypes, shortening development timeframes.

- System Dynamics and Discrete Event Simulation Software AnyLogic and Simul8 allow system dynamics and discrete event modelling for complex systems in manufacturing, logistics, and healthcare. These technologies model system behaviours over time, allowing users to simulate process interactions and dependencies, forecast bottlenecks, and test scenarios in a risk-free virtual environment.

- Multiphysics Simulation Software Multiphysics simulation systems like COMSOL Multiphysics and MATLAB Simulink can simulate fluid flow, heat transfer, and structural mechanics in one model. These instruments are useful in aerospace, automotive, and energy industries where product performance depends on several physical factors.

- Machine Learning and Artificial Intelligence-Driven Tools AI-based modelling tools like TensorFlow and PyTorch help create predictive models from big datasets. Simulation models with AI may learn from data, discover complicated patterns, and predict. These models are useful for system design and analysis in finance, healthcare, and autonomous driving, where data trends can disclose important system insights.

- Digital Twin Platforms IBM’s Digital Twin Exchange and Siemens’ MindSphere offer real-time simulation of physical assets by constructing virtual counterparts that match real-world conditions. Industrial sectors including manufacturing, energy, and smart city planning require constant system monitoring, making digital twins valuable for predictive maintenance, process optimisation, and decision-making.

- Cloud-Based Simulation and Modelling Tools Cloud-based simulation environments like AWS SimSpace Weaver, Microsoft Azure Digital Twins, and Google Cloud Anthos enable large-scale, high-complexity simulations on various devices. Cloud-based solutions can run large simulations without high-end hardware, making them perfect for enterprises wishing to integrate simulation without big infrastructure investments.

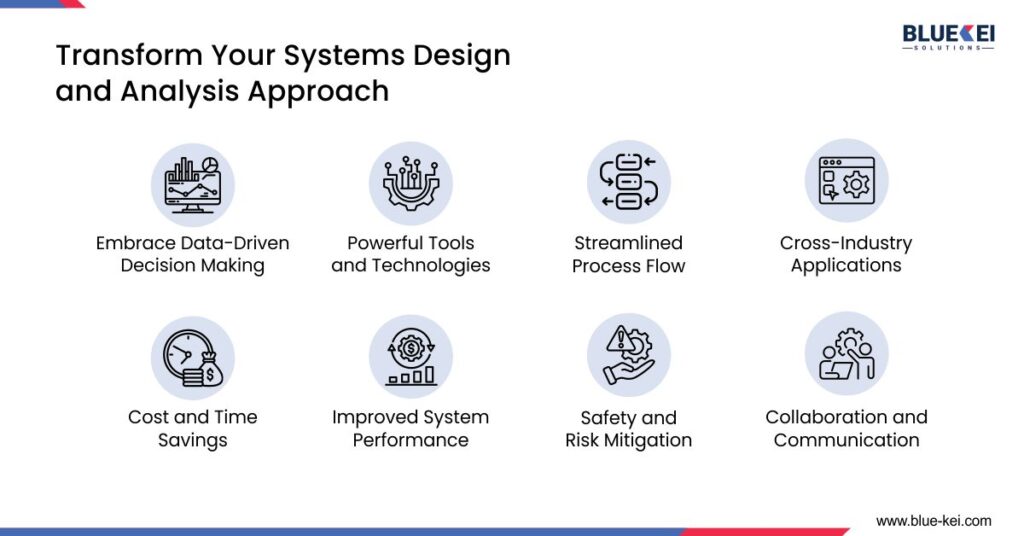

Simulation and modelling offer many advantages. Here are a few mentioned below-

- Improve system design and performance by allowing engineers to test different scenarios and enhance their designs.

- Reduces development costs and time-to-market by identifying and solving issues early in the design process.

- Enhance safety and minimize risks through simulating hazardous scenarios and evaluating safety measures.

- Enhance resource allocation and decision-making by offering insights into system behaviour and performance.

- Promote teamwork and interaction among involved parties through a visual depiction of the system.

- Data Quality and Availability:Obtaining accurate and reliable data is critical for meaningful simulations.

- Computational Resources and Scalability:Complex simulations often demand substantial computing power and scalable infrastructure.

- Model Validation and Verification:Ensuring that the simulation faithfully represents the real-world system is essential.

- Integration with Existing Workflows:Seamless integration with other processes can be challenging and requires careful planning.

- Workforce Skills and Training:Adequate training and a skilled workforce are crucial for successful implementation.

You can transform your simulations from good to great, ensuring proven best practices deliver the insights you need to optimize your business.

- Sharpen Your Focus: Define Clear Objectives and Scope

- Choose Your Weapon Wisely: Select the Right Tools and Techniques

- Data – The Bedrock of Success: Ensure Data Integrity and Accuracy

- Refine and Repeat: Embrace the Iterative Process

- Strength in Numbers: Foster Collaboration and Communication

By integrating these best practices into your simulation and modelling projects, you can unlock their full potential, transforming them from mere exercises into powerful tools for optimizing your business strategies.

Simulation and modelling foster a controlled environment for experimentation, akin to a laboratory of ideas. Within this framework, concepts can be rigorously tested and refined before real-world implementation. This approach, reminiscent of crafting a blueprint, ensures the creation of robust and optimized systems.

SDA serves as the cornerstone for establishing high-performing systems. Simulation and modelling function as potent tools within the SDA arsenal, enabling the exploration of diverse scenarios and their subsequent impact on system behaviour.

BlueKei Solutions is pioneering the mission to empower decision-makers in transforming businesses, for technology adoption and seamless integration through systems engineering. Our customized simulation and modelling consulting services meet your business requirements.

Our team of highly skilled experts utilizes a wide range of tools and technologies to provide top-notch solutions for your business. Moreover, we offer training sessions and seminars to equip your workforce with simulation and modelling expertise.

Contact our specialists today for customized recommendations and move forward in improving your systems.

If you are interested in understanding how to adopt systems engineering and model based systems engineering practices within your organization, reach out to BlueKei Solutions team at info@Blue-Kei.com. We specialize in systems engineering consulting, project executions, process adoptions such as compliance to ISO15288, ARP 4754A, ISO 42020, digital transformations. We can also conduct capability development workshops which are experiential and tailored to your needs. With systems engineering adoption you can address the complexity, manage evolving risks and bring transformation in communication within your organization through digitalization and create the digital thread.