Advancing to BMS Digital Twins using Systems Engineering

Introduction:

In the ever-evolving landscape of the automobile industry, the demand for electric vehicles (EVs) has surged, driven by the need for sustainable and eco-friendly transportation solutions. A critical component in the development of electric vehicles is the Battery Management System (BMS), responsible for monitoring and optimizing the performance of the battery pack. To achieve optimal efficiency, reliability, and innovation in BMS, the integration of Systems Engineering, Model Based Systems Engineering (MBSE), and Digital Thread is proving to be a game-changer, giving rise to the concept of the digital twin.

In the ever-evolving landscape of the automobile industry, the demand for electric vehicles (EVs) has surged, driven by the need for sustainable and eco-friendly transportation solutions. A critical component in the development of electric vehicles is the Battery Management System (BMS), responsible for monitoring and optimizing the performance of the battery pack. To achieve optimal efficiency, reliability, and innovation in BMS, the integration of Systems Engineering, Model Based Systems Engineering (MBSE), and Digital Thread is proving to be a game-changer, giving rise to the concept of the digital twin.

What is Systems Engineering? How can it help in BMS Development?

Systems Engineering being an interdisciplinary approach focuses on the design, integration, and management of complex systems. In the context of BMS development, Systems Engineering provides a holistic framework, ensuring that all components work seamlessly together to achieve the desired performance and reliability.

Systems Engineering being an interdisciplinary approach focuses on the design, integration, and management of complex systems. In the context of BMS development, Systems Engineering provides a holistic framework, ensuring that all components work seamlessly together to achieve the desired performance and reliability.

By adopting a Systems Engineering approach, automakers can better understand the interconnected nature of various components within the electric vehicle ecosystem. This includes the battery pack, sensors, control algorithms, thermal management systems, and more. The comprehensive view allows for optimized designs that enhance the overall efficiency of the BMS.

Model Based Systems Engineering (MBSE):

Model Based Systems Engineering (MBSE) takes Systems Engineering to the next level by utilizing digital models to represent the entire system and its components. In the case of BMS development, MBSE enables engineers to create virtual prototypes, simulate various scenarios, and analyze the performance of the system before physical implementation.

MBSE facilitates collaborative efforts among different engineering disciplines, streamlining the design and development process. Engineers can create detailed models of the BMS, incorporating electrical, thermal, and control aspects. This not only accelerates the development timeline but also ensures a more accurate representation of the system’s behavior under different conditions. Additionally, performing MBSE serves as the catalyst for the generation of Digital Thread. As digital models are refined and enriched during the MBSE process, a seamless flow of information is established, weaving a comprehensive Digital Thread that spans the entire product development lifecycle. This end-to-end connectivity ensures that data generated at any stage of the product development process is accessible and valuable across the entire value chain.

In the context of BMS development, this connectivity enables engineers to make informed decisions, identify potential issues early in the development process, and implement changes rapidly. Moreover, it fosters collaboration and communication between different teams, reducing the risk of miscommunication and ensuring a more efficient development process.

Model Based Systems Engineering (MBSE) takes Systems Engineering to the next level by utilizing digital models to represent the entire system and its components. In the case of BMS development, MBSE enables engineers to create virtual prototypes, simulate various scenarios, and analyze the performance of the system before physical implementation.

MBSE facilitates collaborative efforts among different engineering disciplines, streamlining the design and development process. Engineers can create detailed models of the BMS, incorporating electrical, thermal, and control aspects. This not only accelerates the development timeline but also ensures a more accurate representation of the system’s behavior under different conditions. Additionally, performing MBSE serves as the catalyst for the generation of Digital Thread. As digital models are refined and enriched during the MBSE process, a seamless flow of information is established, weaving a comprehensive Digital Thread that spans the entire product development lifecycle. This end-to-end connectivity ensures that data generated at any stage of the product development process is accessible and valuable across the entire value chain.

In the context of BMS development, this connectivity enables engineers to make informed decisions, identify potential issues early in the development process, and implement changes rapidly. Moreover, it fosters collaboration and communication between different teams, reducing the risk of miscommunication and ensuring a more efficient development process.

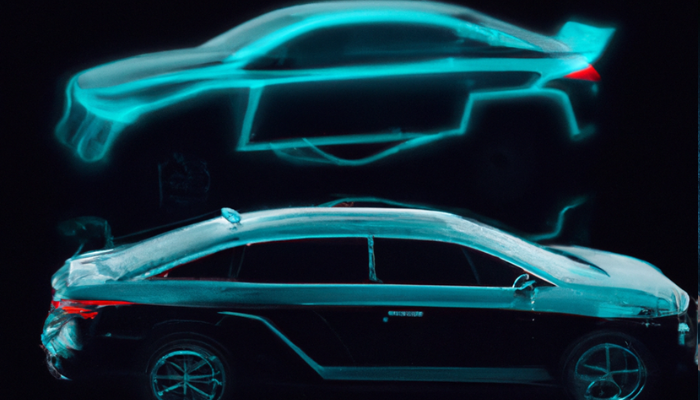

The Digital Twin: A Virtual Replica of the BMS:

At the heart of this integrated approach lies the concept of the Digital Twin, a virtual replica of the physical BMS. This virtual model is continuously updated in real-time through the Digital Thread, reflecting the current state of the physical system. The Digital Twin allows engineers to monitor and analyze the BMS’s performance, predict potential issues, and optimize its operation throughout its lifecycle. Advantages of a Digital Twin for BMS Development:

1. Real-Time Monitoring and Analysis: Engineers can continuously monitor the BMS’s performance, enabling early detection of anomalies and potential issues.

2. Predictive Maintenance: By analyzing data from the Digital Twin, predictive maintenance strategies can be implemented, minimizing downtime and extending the lifespan of the BMS.

3. Performance Optimization: The Digital Twin provides a platform for testing and implementing improvements, leading to continuous optimization of the BMS.

4. Scenario Simulation: Engineers can simulate various operating conditions and scenarios to ensure that the BMS performs reliably under diverse circumstances.

At the heart of this integrated approach lies the concept of the Digital Twin, a virtual replica of the physical BMS. This virtual model is continuously updated in real-time through the Digital Thread, reflecting the current state of the physical system. The Digital Twin allows engineers to monitor and analyze the BMS’s performance, predict potential issues, and optimize its operation throughout its lifecycle. Advantages of a Digital Twin for BMS Development:

1. Real-Time Monitoring and Analysis: Engineers can continuously monitor the BMS’s performance, enabling early detection of anomalies and potential issues.

2. Predictive Maintenance: By analyzing data from the Digital Twin, predictive maintenance strategies can be implemented, minimizing downtime and extending the lifespan of the BMS.

3. Performance Optimization: The Digital Twin provides a platform for testing and implementing improvements, leading to continuous optimization of the BMS.

4. Scenario Simulation: Engineers can simulate various operating conditions and scenarios to ensure that the BMS performs reliably under diverse circumstances.

Conclusion:

In the pursuit of developing cutting-edge Battery Management Systems for electric vehicles, Systems Engineering, Model Based Systems Engineering, and the Digital Thread are indispensable tools. The integration of these methodologies culminates in the creation of a Digital Twin, offering unprecedented insights, predictive capabilities, and optimization opportunities throughout the product development lifecycle. As the automotive industry continues its shift towards electrification, embracing these advanced engineering approaches will undoubtedly propel the development of more efficient, reliable, and innovative Battery Management Systems.

In the pursuit of developing cutting-edge Battery Management Systems for electric vehicles, Systems Engineering, Model Based Systems Engineering, and the Digital Thread are indispensable tools. The integration of these methodologies culminates in the creation of a Digital Twin, offering unprecedented insights, predictive capabilities, and optimization opportunities throughout the product development lifecycle. As the automotive industry continues its shift towards electrification, embracing these advanced engineering approaches will undoubtedly propel the development of more efficient, reliable, and innovative Battery Management Systems.

If you are interested in understanding how to adopt systems engineering and model based systems engineering practices within your organization, reach out to BlueKei Solutions team at info@Blue-Kei.com. We specialize in systems engineering consulting, project executions, process adoptions such as compliance to ISO15288, ARP 4754A, ISO 42020, digital transformations. We can also conduct capability development workshops which are experiential and tailored to your needs. With systems engineering adoption you can address the complexity, manage evolving risks and bring transformation in communication within your organization through digitalization and create the digital thread.

Post Views: 351