Introduction:

In the dynamic landscape of modern engineering, the development of complex systems, especially in the automotive and aerospace industries, demands innovative approaches that can handle the intricacies of integration, optimization, and scalability. Two key methodologies, Systems Engineering (SE) and Model-Based Systems Engineering (MBSE), have emerged as pivotal in shaping the future of Zonal Architectures. In this blog post, we explore how SE and MBSE are revolutionizing the development of Zonal Architectures, driving efficiency, reliability, and adaptability to new heights.

In the dynamic landscape of modern engineering, the development of complex systems, especially in the automotive and aerospace industries, demands innovative approaches that can handle the intricacies of integration, optimization, and scalability. Two key methodologies, Systems Engineering (SE) and Model-Based Systems Engineering (MBSE), have emerged as pivotal in shaping the future of Zonal Architectures. In this blog post, we explore how SE and MBSE are revolutionizing the development of Zonal Architectures, driving efficiency, reliability, and adaptability to new heights.

Understanding Zonal Architectures

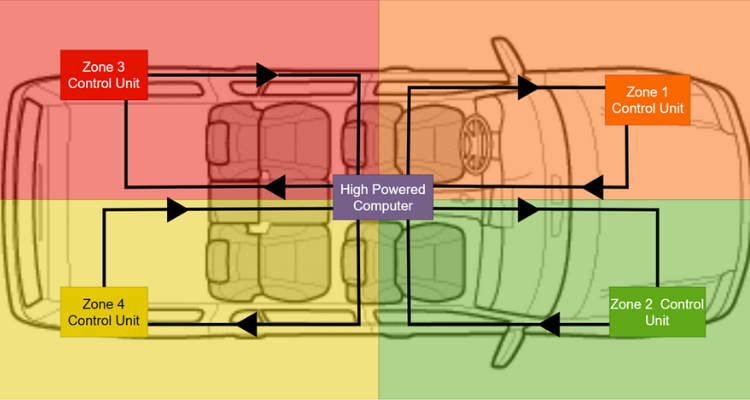

Zonal architectures represent a departure from the conventional centralized Electronic Control Unit (ECU) model. In this new approach, vehicles are divided into functional zones, each with its dedicated set of controllers known as Distributed Control Units (DCUs). These zones encompass various aspects such as powertrain, body control, and infotainment, allowing for a more modular and scalable approach to vehicle design.

The development of Zonal Architectures, characterized by the decentralization of functionalities into distinct zones, brings forth a set of unique challenges. These challenges stem from the need to balance modularity, scalability, and adaptability while ensuring seamless integration and interoperability across distributed zones.

One of the primary challenges in adopting zonal architectures is the complexity associated with integration. Coordinating the interactions between different zones and ensuring seamless integration of various DCUs can be a daunting task due to the diverse functions and interfaces within the vehicle. Furthermore, the lack of industry-wide standards for zonal architectures can lead to interoperability issues, making it challenging to ensure effective collaboration between components from different manufacturers.

Scalability and flexibility are essential considerations, requiring zonal architectures to accommodate future technological advancements and additional features. However, balancing these advantages with the associated development costs becomes a key consideration for manufacturers. The introduction of zonal architectures also demands a shift in the skill set and training of automotive professionals, emphasizing the need for adaptation to the new distributed system.

Zonal Architectures often require collaboration across diverse engineering disciplines, such as electronics, software, and mechanical engineering. Ensuring effective communication and collaboration among these interdisciplinary teams becomes extremely crucial. Diagnostic complexity is another hurdle, as troubleshooting issues in a zonal architecture proves to be more intricate than in a centralized system.

Zonal Architectures often require collaboration across diverse engineering disciplines, such as electronics, software, and mechanical engineering. Ensuring effective communication and collaboration among these interdisciplinary teams becomes extremely crucial. Diagnostic complexity is another hurdle, as troubleshooting issues in a zonal architecture proves to be more intricate than in a centralized system.

Regulatory compliance poses a challenge, as zonal architectures must meet safety, emissions, and other regulatory standards. This necessitates additional testing and validation processes to ensure adherence to industry regulations. Reliability and redundancy concerns emerge, highlighting the importance of ensuring the reliability of individual components within each zone and implementing redundancy mechanisms to prevent single points of failure.

Zonal architectures represent a departure from the conventional centralized Electronic Control Unit (ECU) model. In this new approach, vehicles are divided into functional zones, each with its dedicated set of controllers known as Distributed Control Units (DCUs). These zones encompass various aspects such as powertrain, body control, and infotainment, allowing for a more modular and scalable approach to vehicle design.

The development of Zonal Architectures, characterized by the decentralization of functionalities into distinct zones, brings forth a set of unique challenges. These challenges stem from the need to balance modularity, scalability, and adaptability while ensuring seamless integration and interoperability across distributed zones.

One of the primary challenges in adopting zonal architectures is the complexity associated with integration. Coordinating the interactions between different zones and ensuring seamless integration of various DCUs can be a daunting task due to the diverse functions and interfaces within the vehicle. Furthermore, the lack of industry-wide standards for zonal architectures can lead to interoperability issues, making it challenging to ensure effective collaboration between components from different manufacturers.

Scalability and flexibility are essential considerations, requiring zonal architectures to accommodate future technological advancements and additional features. However, balancing these advantages with the associated development costs becomes a key consideration for manufacturers. The introduction of zonal architectures also demands a shift in the skill set and training of automotive professionals, emphasizing the need for adaptation to the new distributed system.

Zonal Architectures often require collaboration across diverse engineering disciplines, such as electronics, software, and mechanical engineering. Ensuring effective communication and collaboration among these interdisciplinary teams becomes extremely crucial. Diagnostic complexity is another hurdle, as troubleshooting issues in a zonal architecture proves to be more intricate than in a centralized system.

Zonal Architectures often require collaboration across diverse engineering disciplines, such as electronics, software, and mechanical engineering. Ensuring effective communication and collaboration among these interdisciplinary teams becomes extremely crucial. Diagnostic complexity is another hurdle, as troubleshooting issues in a zonal architecture proves to be more intricate than in a centralized system.

Regulatory compliance poses a challenge, as zonal architectures must meet safety, emissions, and other regulatory standards. This necessitates additional testing and validation processes to ensure adherence to industry regulations. Reliability and redundancy concerns emerge, highlighting the importance of ensuring the reliability of individual components within each zone and implementing redundancy mechanisms to prevent single points of failure.

How can SE and MBSE help?

Systems Engineering (SE) and Model-Based Systems Engineering (MBSE) emerge as powerful tools to address the challenges associated with zonal architectures. These methodologies provide a holistic approach to system design and integration, managing the complexity of integrating different zones. Through the development of standardized processes and methodologies, SE can facilitate better interoperability and compatibility among components from different manufacturers.

Systems Engineering emphasizes a holistic approach to problem-solving, viewing the entire system as an interconnected entity. In the context of Zonal Architectures, SE ensures that every component, function, and interaction is considered within the broader framework. This holistic perspective is essential for defining the boundaries and interfaces of different zones.

Zonal Architectures demand a meticulous understanding of requirements, and SE excels in managing these intricacies. Systems engineers systematically capture, analyze, and prioritize requirements, ensuring that the zonal architecture meets the functional, performance, and safety criteria. This rigorous requirement management is crucial for the successful implementation of Zonal Architectures.

SE provides a structured methodology for trade-off analysis and optimization. In the development of Zonal Architectures, where decisions regarding the distribution of functions across zones are critical, systems engineers use analytical tools to evaluate different options. This ensures that the chosen architecture aligns with overarching goals such as efficiency, reliability, and scalability.

Model-Based Systems Engineering (MBSE) allows for the creation of detailed system models, enabling a thorough analysis of potential cybersecurity vulnerabilities. This proactive approach aids in designing robust security measures at the system level, protecting each zone from cyber threats. MBSE also facilitates virtual testing and simulation, streamlining the diagnostic process by providing a virtual environment for identifying and troubleshooting issues within specific zones.

MBSE leverages visual models to represent the complexities of Zonal Architectures. Through graphical representations, engineers can visualize the interconnections, dependencies, and hierarchies within and between zones. This enhances communication, collaboration, and understanding among multidisciplinary teams.

Systems Engineering (SE) and Model-Based Systems Engineering (MBSE) emerge as powerful tools to address the challenges associated with zonal architectures. These methodologies provide a holistic approach to system design and integration, managing the complexity of integrating different zones. Through the development of standardized processes and methodologies, SE can facilitate better interoperability and compatibility among components from different manufacturers.

Systems Engineering emphasizes a holistic approach to problem-solving, viewing the entire system as an interconnected entity. In the context of Zonal Architectures, SE ensures that every component, function, and interaction is considered within the broader framework. This holistic perspective is essential for defining the boundaries and interfaces of different zones.

Zonal Architectures demand a meticulous understanding of requirements, and SE excels in managing these intricacies. Systems engineers systematically capture, analyze, and prioritize requirements, ensuring that the zonal architecture meets the functional, performance, and safety criteria. This rigorous requirement management is crucial for the successful implementation of Zonal Architectures.

SE provides a structured methodology for trade-off analysis and optimization. In the development of Zonal Architectures, where decisions regarding the distribution of functions across zones are critical, systems engineers use analytical tools to evaluate different options. This ensures that the chosen architecture aligns with overarching goals such as efficiency, reliability, and scalability.

Model-Based Systems Engineering (MBSE) allows for the creation of detailed system models, enabling a thorough analysis of potential cybersecurity vulnerabilities. This proactive approach aids in designing robust security measures at the system level, protecting each zone from cyber threats. MBSE also facilitates virtual testing and simulation, streamlining the diagnostic process by providing a virtual environment for identifying and troubleshooting issues within specific zones.

MBSE leverages visual models to represent the complexities of Zonal Architectures. Through graphical representations, engineers can visualize the interconnections, dependencies, and hierarchies within and between zones. This enhances communication, collaboration, and understanding among multidisciplinary teams.

MBSE facilitates rigorous requirements traceability, linking every component and function back to the defined requirements. In Zonal Architectures, where modular functionalities are distributed across different zones, maintaining a clear traceability matrix is essential. MBSE tools automate this process, ensuring consistency and alignment with the system requirements.

Zonal Architectures benefit greatly from simulations and prototypes, and MBSE enables the creation of virtual models for testing and validation. Engineers can simulate the behavior of different zones under various conditions, identify potential issues, and refine the architecture before physical implementation. This iterative process significantly reduces development time and costs.

SE and MBSE support a modular approach to system design, creating flexible and scalable models that enable engineers to adapt zonal architectures to accommodate new technologies and features without extensive redesign. By emphasizing efficient resource allocation and optimization, SE can help strike a balance between the benefits of zonal architectures and the associated development costs.

Zonal Architectures benefit greatly from simulations and prototypes, and MBSE enables the creation of virtual models for testing and validation. Engineers can simulate the behavior of different zones under various conditions, identify potential issues, and refine the architecture before physical implementation. This iterative process significantly reduces development time and costs.

SE and MBSE support a modular approach to system design, creating flexible and scalable models that enable engineers to adapt zonal architectures to accommodate new technologies and features without extensive redesign. By emphasizing efficient resource allocation and optimization, SE can help strike a balance between the benefits of zonal architectures and the associated development costs.

Conclusion:

In conclusion, zonal architectures represent a transformative leap in the automobile industry’s pursuit of innovation. While challenges exist, Systems Engineering and Model-Based Systems Engineering offer comprehensive solutions to navigate and overcome these hurdles. By adopting these methodologies, the automotive industry can harness the full potential of zonal architectures, paving the way for safer, more efficient, and technologically advanced vehicles.

In conclusion, zonal architectures represent a transformative leap in the automobile industry’s pursuit of innovation. While challenges exist, Systems Engineering and Model-Based Systems Engineering offer comprehensive solutions to navigate and overcome these hurdles. By adopting these methodologies, the automotive industry can harness the full potential of zonal architectures, paving the way for safer, more efficient, and technologically advanced vehicles.

Post Views: 3